When “Just Good Enough” isn’t Good Enough

While evaluating high-speed network test equipment, it may be tempting to forgo deep physical layer testing capabilities to save money and reduce testing complexities. In some cases, these ‘just good enough’ solutions appear to fit the bill, but lack of deep insights can lead to product re-designs, longer development cycles or systemic failures in the field. Even worse is the sinking realization you have invested in test equipment that falls short in critical areas. This blog should help you define your requirements—and better understand when ‘just good enough’ just doesn’t cut it.

A Single, Undetected Error

Your product passed BER tests, but without an error fingerprint, unseen problems evaded the basic diagnostics. You shipped the order and your customer found problems in QA or systems tests. Now the challenge is identifying the root cause of the problem using the same tools that missed the errors in the first place. The manual discovery and identification process that follows can take days or even weeks. Then comes the redesign that further delays your time-to-revenue and your customer’s time-to-market. These events happen frequently, and just one incident like this can erase your savings on the testing tools—and even worse, damage credibility with your customer.

Depth and Breadth Coverage

During the past 25 years, we have rapidly evolved from simple 10G client optics based on NRZ signaling to 800Gb pluggable coherent optics using 100G per lane PAM-4 SERDES.

The breadth and depth of testing required to develop, debug and validate these optics now has to be multiple domain, not isolated basic tests that were used at 100Gb and below. The high degree of complexity in the modern DSP based SERDES, which is closely bound to firmware and the photonics, means any testing needs to be multi-domain aware and give more than a simple scalar result.

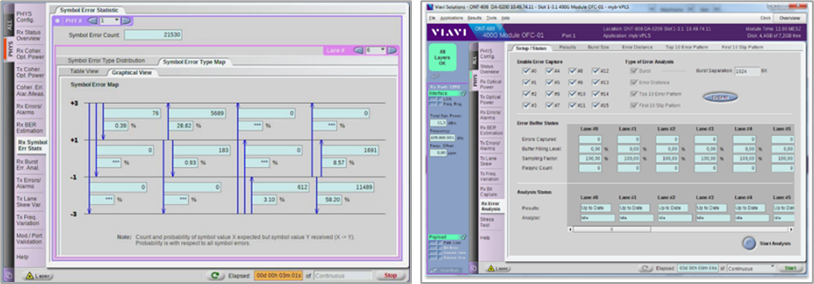

The VIAVI ONT provides deep insights in user-friendly GUIs to identify problems early in development

The ‘simple’ BER test from the NRZ era is no longer applicable in the era of PAM-4 and DSP based SERDES. The always ‘errored’ PAM-4 link means any error testing must be fully aware of the error fingerprint. Some errors are natural and based on the random noise that will occur in both the optical and electrical channel, but other errors occur because of the DSP equalizer dynamics, noise, crosstalk and channel impairments like reflections, all of which need to be fully understood during the design and validation phase. Tiny changes in parameters which might occur due to temperature, operating voltage or clock and data phase can significantly change the BER which will impact the FEC ability to correct errors with enough margin.

Worse yet are catching rare dynamic events which cause error bursts that a FEC could not correct leading to uncorrected code words and link flaps. Basic BER tests show an elevated error rather than any insight to help fingerprint and get to the root cause to fix the issue.

What is ‘Just Good Enough’ for You?

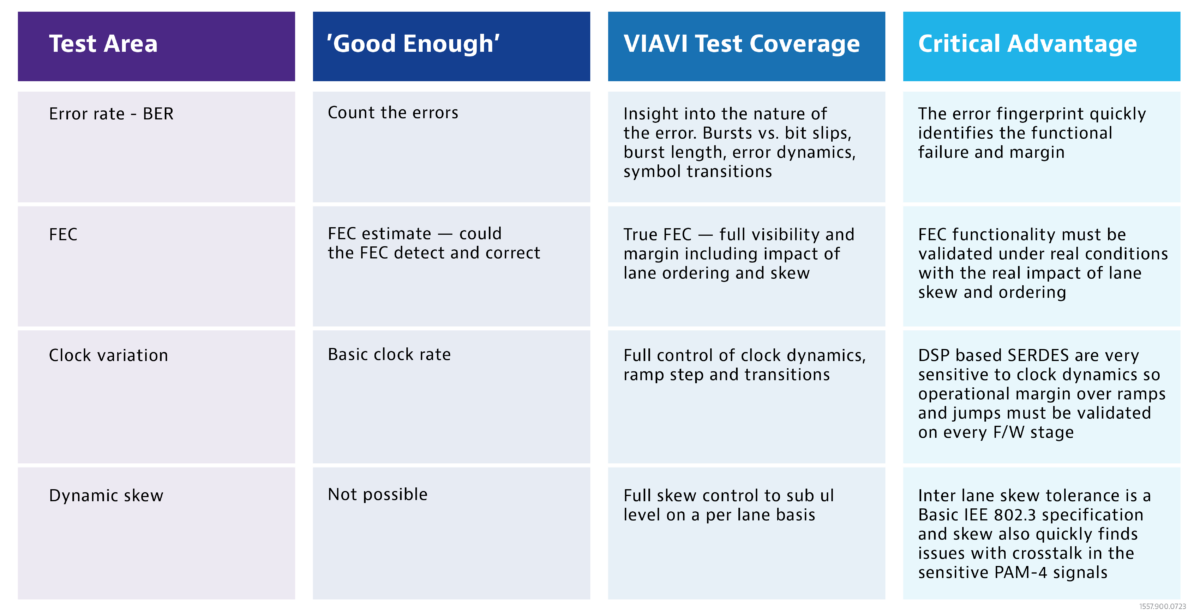

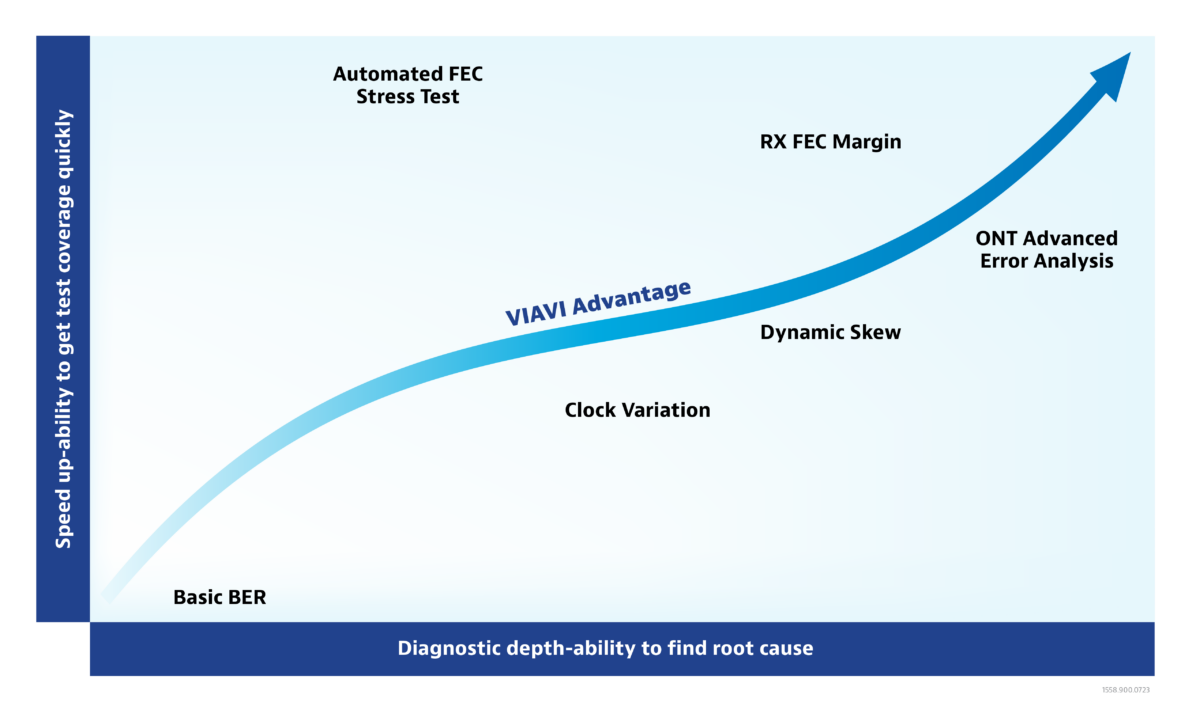

VIAVI has a very experienced team of application engineers and one of the most frequent questions they are asked by our customers is ‘what is just good enough’ to test. We work with them to show that the path to fast product development and debugging is based on insightful testing which diagnoses and validates margin. With the conventional ‘just good enough’ testing, all you really get is basic connectivity information. The real value is getting the fingerprint of each link. With this you have a true picture of how well the design works and the margin in the implementation. This is more critical when the design is a blend of hardware, DSP and firmware like 400Gb and 800Gb today.

Some limitations of “Just Good Enough” are illustrated below:

Good, Bad…and the Details In Between

The real issue with ‘good enough’ is that you only know the most basic information at a moment in time. You cannot determine where you are on a line between ‘good’ and ‘bad’ and how the smallest change can flip your design from working perfectly—to random error bursts.

My best advice is to avoid shortcuts so you can have confidence in your designs. Catch problems early—and don’t be misled by superficial, ‘good enough’ tests. It will save you time, money—and maybe even a customer—in the long run.

The VIAVI ONT provides the ideal combination of testing depth and speed

VIAVI Can Help!

To get an insightful view of your high-speed optical module performance using testing solutions that meet the highest industry standards—speak to our VIAVI applications team.

Also, please read our other recent blogs: Integrated Testing Simplifies DCO Complexities, What’s All the 800G Stuff? Evolution, Revolution…or Both?, and What’s All This Error Fingerprint Stuff?