Enhanced TDR – Revolutionizing Fiber Optic Testing

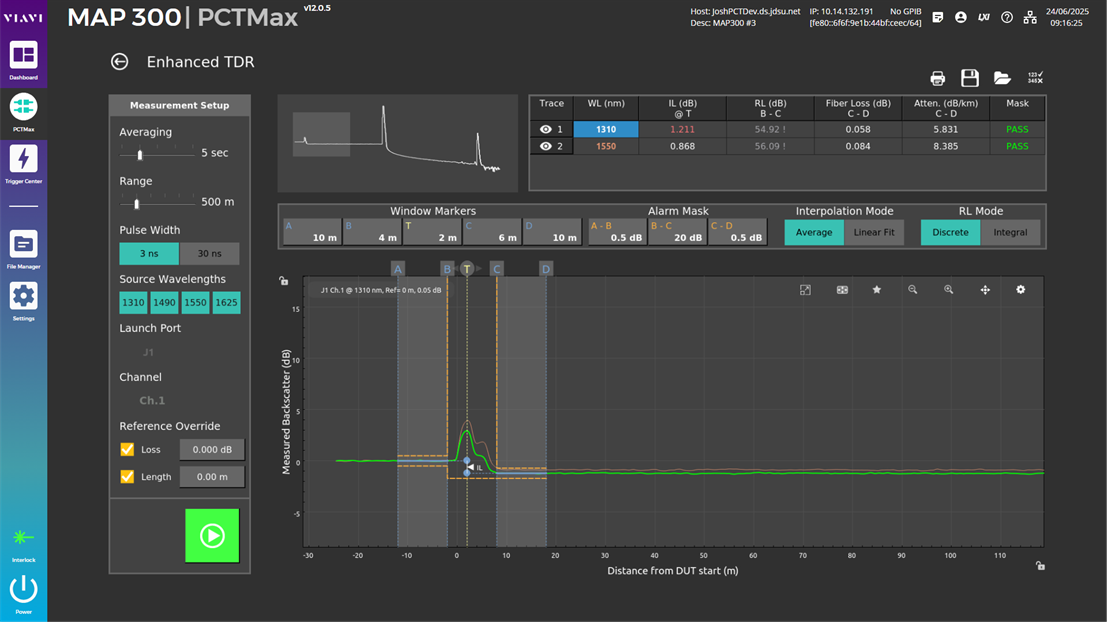

In the rapidly evolving world of AI data centers, VIAVI Solutions is at the forefront with its innovative enhancements to the MAP testing platform. One standout feature is Enhanced Time Domain Reflectometry (TDR), a software addition to the PCT infrastructure that simplifies and accelerates fiber optic testing.

What is Enhanced TDR?

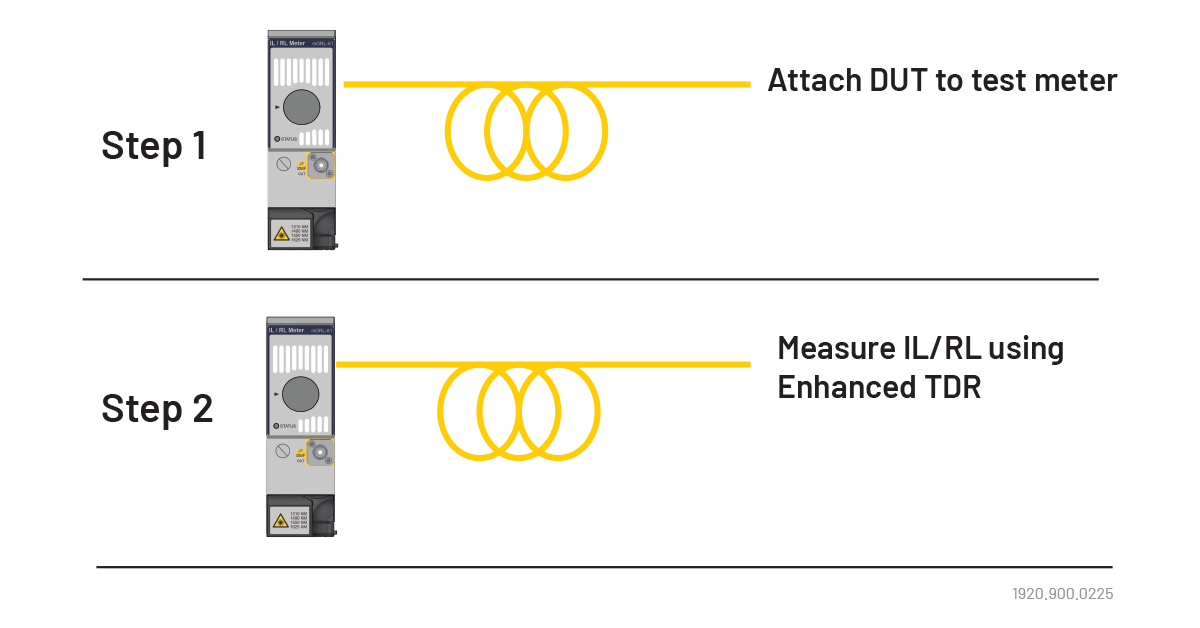

Enhanced TDR is designed to measure the insertion loss and return loss of a Device Under Test (DUT) without the need for a power meter. This advancement significantly improves test throughput by eliminating a common procedural bottleneck. Traditional insertion loss measurements, while precise, can be time-consuming and costly. Enhanced TDR offers a streamlined alternative, particularly beneficial in high-speed environments where efficiency is paramount.

Enhanced TDR removes the need to connectorize the end of the DUT streamlining and accelerating the testing process

How Does It Work?

Enhanced TDR operates by measuring the backscatter from the fiber system before and after the connector under test. This requires a minimum DUT length of 5 meters and a test lead of at least 5 meters, though longer lengths up to 50 meters are preferable, with the system ultimately being able to measure DUTs of up to 10 km.

Benefits and Trade-offs

While Enhanced TDR takes marginally longer to execute measurements, it dramatically reduces material costs and overall process time leading to increased throughput. This makes it a groundbreaking leap forward in testing technology. However, users should be aware of the trade-offs in speed and dynamic range. Whereas standard insertion loss measurements with the PCT have insertion loss dynamic ranges exceeding 40dB, the Enhanced TDR application has a dynamic range of approximately 10dB.

Automation and Process Control

As part of the MAP framework, Enhanced TDR is process-designed and automation-enabled. Every function can be controlled remotely via SCPI commands, allowing for seamless integration into automated workflows and ERP or OMS infrastructures. This includes querying results and using process control tools like data masks on the graphical user interface (GUI).

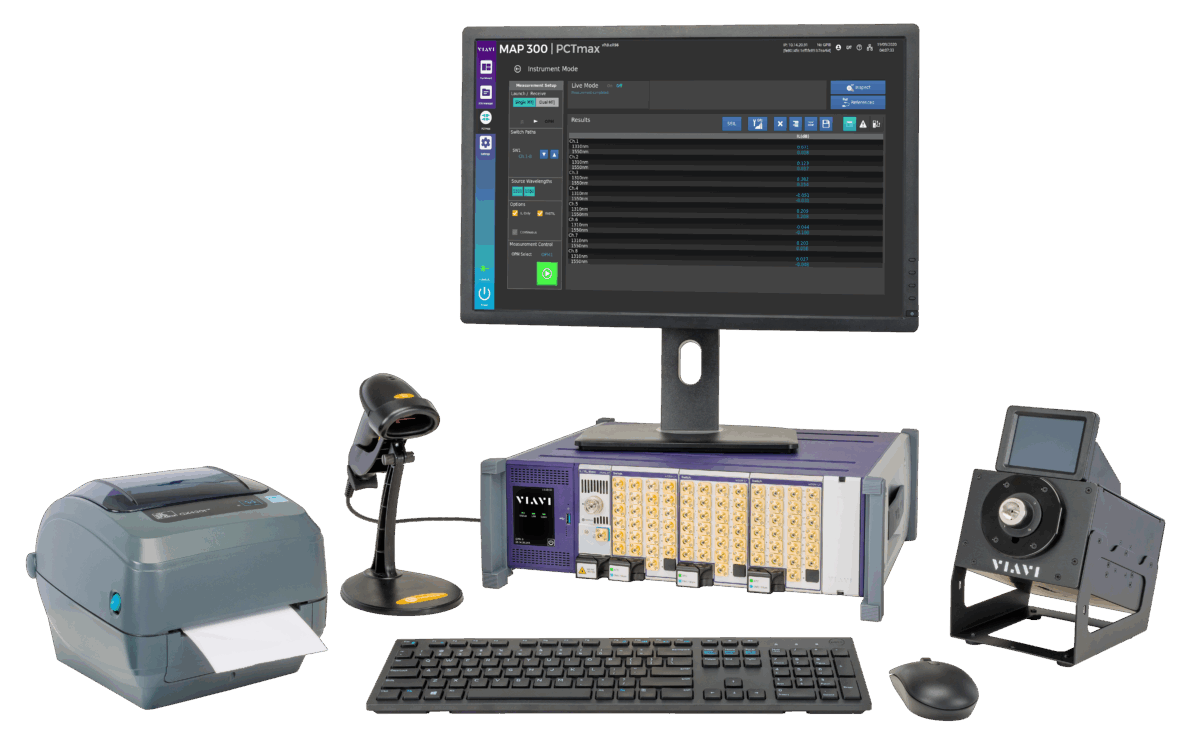

MAP-300 PCT Process Control GUI

Future Enhancements

Looking ahead, VIAVI plans to incorporate Enhanced TDR as a troubleshooting tool within Instrument mode. This will enable users to launch Enhanced TDR measurements on channels where traditional IL/RL measurements have failed, helping to identify and address the causes of failures. Additionally, Enhanced TDR will be included in the PCT’s onboard test scripting mode, allowing operators to execute tests and automatically log results.

Conclusion

Enhanced TDR within the PCT architecture offers unparalleled access for testers to measure IL and RL without a power meter, reducing costs and steps in the process while increasing overall efficiency. With remote commands and scripting capabilities, users can easily automate their workflows, making Enhanced TDR a valuable addition to any testing environment.

Many peripherals can be easily added to the PCT workflow

VIAVI Can Help!

For additional details and illustrations, read our related whitepaper: Novel Insertion Loss Measurements – VIAVI PCT Enhanced TDR. It illustrates specific steps in the process. Or, contact a VIAVI product expert.