Building Quality Passive Optical Networks (PON) at Scale: Centralized Test

Passive optical networks (PON) have revolutionized high-speed internet connectivity by providing efficient fiber-based broadband services. To ensure the quality and performance of these networks, a robust certification process is essential. In this blog, we will explore a new centralized test approach to certifying the construction of passive optical networks and look at the kinds of issues it can help address and benefits it can deliver.

Certification plays a crucial role in PON construction for several reasons:

- Investment protection: You need to ensure you are getting what you are paying for; no investor should consider parting with any money for PON build/deployment without getting a fully certified network in return.

- Reliability: PON networks must deliver reliable connectivity to meet customer expectations. Certification ensures that the installed infrastructure adheres to industry standards and will perform as intended over the long term.

- Quality assurance: Certification guarantees that the construction process and the materials used adhere to stringent quality standards. This ensures the network can withstand environmental factors and deliver consistent performance.

- Efficiency: Proper certification allows network operators to detect and rectify potential issues during the construction phase, minimizing downtime and costly repairs later.

Lack of comprehensive testing or incorrect test procedures combined with other factors associated with the traditional PON build—like the PON not being built sequentially from the central/local office out and fiber sections being built and connected out of sequence—has led to knock-on effects when connecting paying customers. We’ve seen a significant number of large tier-1 service providers from around the world experiencing first-time installation failure rates of up to, and in some cases over, 30% for FTTH customers. Needless to say, that’s shocking and not viable for those service providers in terms of additional troubleshooting/install truck rolls, unnecessary drop fiber replacements and delays with time to revenue i.e., billing customers. Plus, all those additional truck rolls can put a dent in environmental targets to reduce carbon footprints.

To help reduce this knock-on effect of poor customer install success rates caused by poor PON build quality, VIAVI has developed a centralized test application for its remote fiber test system (ONMSi) specifically for PON build certification.

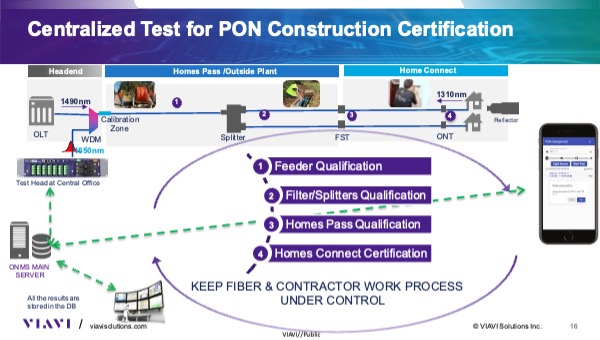

So, what exactly is centralized test for PON build certification? Instead of a tech running around with an OTDR performing tests and storing results in the field for later upload/submission, techs are equipped with optical reflectors and a mobile test app installed on a phone or tablet. The test equipment, essentially a rack mounted OTDR, is installed at the central or local office and managed by a centralized test system, with PON construction application, and connected to the web/cloud for external access. The centralized test approach also requires that PON is built in a logical and sequential order from the central/local office outward to the drop points/terminals. Once the first section of feeder fiber connected to the central/local office has been laid and all the fiber splices made it can be tested. The tech in the field connects a reflector to the fiber and uses the mobile test app to trigger a remote test from the central/local office, the result of which is automatically stored. If the fiber passes, that fiber/phase of construction is marked as done and complete, allowing real-time reporting on project progress. Next the PON splitters are connected, and tests can be run to confirm good feeder fiber to splitter connection. Next the distribution fibers can be laid and again tested/certified as you go.

The same centralized test equipment can be enhanced and expanded with integrated optical switches so that multiple PONs can be tested with the same equipment, offering coverage efficiencies.

This approach offers several advantages for the build acceptance process:

- Simplified Testing Process: Eliminates the need to conduct tests at multiple points out in the network, streamlining the certification process for faster and more efficient network certification. No requirement for techs to understand setup or use of OTDR.

- Compliance to Method of Procedure (MoP): Tests are predefined according to the network design and stage/section/location of the PON being testing, ensuring no deviations.

- 100% certification: Due to time savings (thanks to speed of test, auto result storage/auditing), more fiber can be tested in the same time as the traditional field instrument based approach. So instead certifying a sample of the PON you can achieve 100% and remove any ambiguity during build close or handover phases.

- Efficiency: Any issues or problems with fibers or splices, etc. can be dealt with before techs leave a site, reducing the future truck rolls for rework/mop-up maintenance.

- Enhanced Project Management: The centralized test approach provides a comprehensive view of the network’s construction progress in real-time.

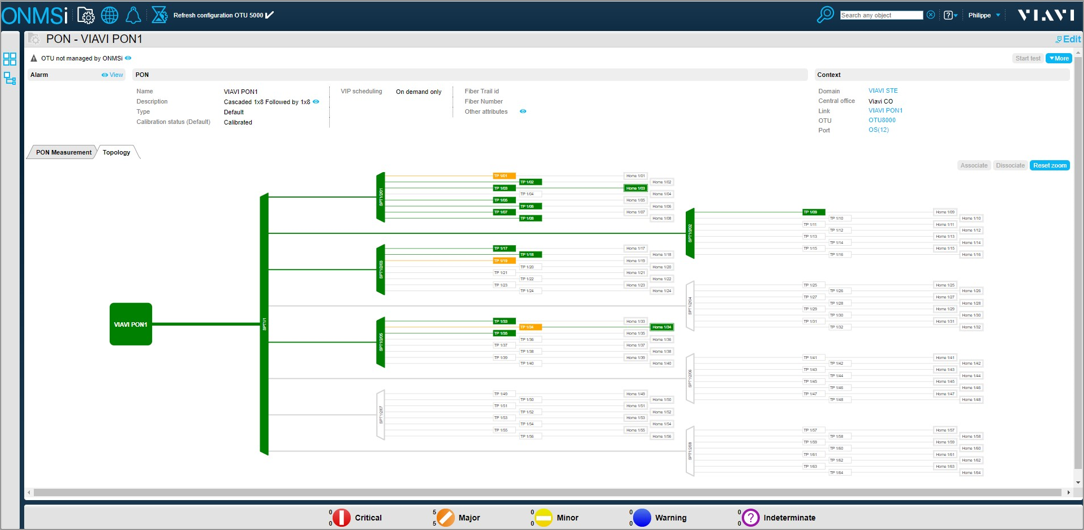

RFTS PON construction progress diagram

All of this adds up to faster PON deployment, with higher quality, better reliability, and faster time to revenue.

In addition to these benefits, once certification is complete, the same system can be turned into a tool for tracking installs, by adding fiber analytics capabilities (like those available with the VIAVI ONMSi Fiber Analytics and Monitoring packages, something we will look at in a future blog). The same optical reflectors and test app can be used to confirm service activations/installations and to track homes passed consumption. Furthermore, in parallel the system can monitor what has just been built to proactively identify any developing issues to maximize service quality and minimize downtime. So, the usefulness of such a system is diverse, and overall ROI is enhanced as the system supports more than just the build certification part of a PON’s lifecycle.

The centralized test approach is a game-changer for certifying the construction of PON. Its streamlined testing process, automated real-time reporting and monitoring capabilities, and enhanced network management lead to higher-quality networks with improved first-time service activation and install rates, something that VIAVI has proved in the real world with a number of Tier-1 service providers, like BT Openreach (UK) and Proximus (BE). It’s also something that the alternatives to the big national network/service providers (Alt-Nets) are embracing in order to satisfy their investors by demonstrating they are getting what they paid for, value for money, and good ROI.

The result of adopting a centralized test approach, using a remote fiber test and monitoring solution to certify construction quality, has seen the number successful installs per week/month rise on average by threefold (x3).

Now don’t get me wrong, the traditional OTDR in the field approach and centralized PON certification approach are both valuable, necessary methods for ensuring the quality and performance of PON. Each approach has its advantages. Network operators should carefully consider their specific requirements and network size to choose the most suitable certification approach for their PON construction process. By embracing the right method, network owners/operators can deliver reliable and high-performance fiber optic broadband services, meeting the demands of investors, shareholders, and customers.

Download our Automated End-to-End PON Fiber Test White Paper to learn more.

Dou glas Clague is currently solutions marketing manager for fiber optic field solutions at VIAVI. Doug has over 20 years of experience in test and measurement with a primary focus on fiber optics and cable technologies, supporting the telecommunications industry. Prior to VIAVI, Doug held positions as manufacturing engineer, solutions engineer and business development manager. Doug has participated on numerous industry panels around fiber and cable technology trends. He attended Brunel University in London and graduated with an honors degree in electrical and electronic engineering.

glas Clague is currently solutions marketing manager for fiber optic field solutions at VIAVI. Doug has over 20 years of experience in test and measurement with a primary focus on fiber optics and cable technologies, supporting the telecommunications industry. Prior to VIAVI, Doug held positions as manufacturing engineer, solutions engineer and business development manager. Doug has participated on numerous industry panels around fiber and cable technology trends. He attended Brunel University in London and graduated with an honors degree in electrical and electronic engineering.