What’s All This Insertion Cycle Stuff?

One of the questions we get asked now and then is on the connector life in our ONT products. Pluggable optical modules can be plugged in and out of our test sets, both as part of their test and validation but also in normal applications engineers will plug in and out different optical interfaces in their day-to-day test applications. Make no mistake, at VIAVI we take great care in the selection of our component vendors and even ‘boring’ connectors get a lot of study.

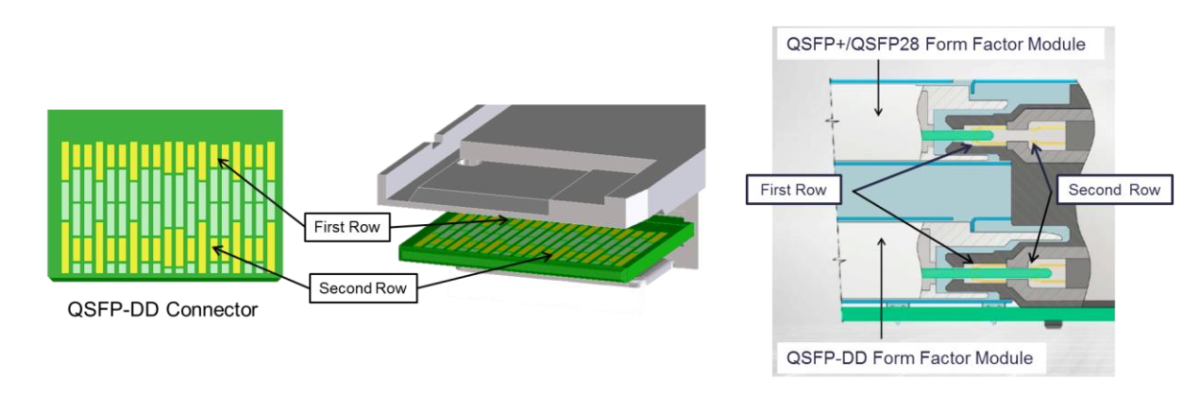

Optical modules, like QSFP-28 and QSFP-DD, use a host connector (an actual physical connector) and a module connector which is normally part of the module PCB. The connector is designed as a ‘wiping contact’, so each insertion and extraction causes the connector fingers in the host module to wipe over the pads on the PCB. Both are normally coated in a precious metal (like gold) and the wiping action helps clean the surface on each mating cycle. Of course, each mating cycle does cause a tiny amount of wear, but the finger pressure and dimensions are extremely closely controlled. This is one reason why connector companies need to invest millions in the precision machines that make their connector parts. The connector has to provide power to the module (this could be close to 20W at 3.3V for a coherent QSFP-28) as well as provide the high performance signal integrity needed for 28 Gbd PAM-4 parallel lanes.

The QSFP-DD MSA does set standards for connector mating cycles – a minimum of 100 for the host connector and 50 for the module connector. In our experience, the connectors and modules can last far beyond this. This is especially true if care is taken in the insertion and extraction and the mating services are kept free of contamination. Another factor to consider is that the module mating fingers are somewhat exposed in a QSFP style package, so being careful with storage helps. We certainly would not recommend handling QSFP-DDs after eating a bucket of spicy buffalo wings!

Having said all this, the only observable issues have been due to catastrophic damage from excessive force, especially if the connector cage or module body has experienced mechanical damage. Of course, we always recommend close inspection before you connect. Indeed, “Inspect before you connect” has been the motto of my fiber optic colleagues for many years!

Thanks for reading. To find out more about FEC, PAM-4 and many other Transport Network topics please visit the VIAVI High-Speed Network Test page.