Fiber Connectors: When a speck of dust looms as large as an iceberg

When a speck of dust looms as large as an iceberg

When the RMS Titanic floated out of its drydock in 1911, its architect and owners hailed it as “unsinkable” and the most advanced ship of its time. But on the fateful night of April 14th, 1912 those claims were put to the test, and the Titanic sank, doomed because of an iceberg no one saw coming until it was too late.

A highly touted technological advancement in human ingenuity and engineering literally sank because of frozen water. Ironic.VIAVI Staff

It’s also ironic that something as advanced as an enterprise network can be derailed by microscopic specks of debris, and yet, that’s exactly what happens when you allow contaminated fiber end faces into your data center. An efficient network is the back bone of any successful business, and there isn’t room for connectivity issues or downtime.

Multiple studies have shown connector contamination is the single greatest cause of fiber-related failure—and the industry knows this. So why are contaminated end faces still such a problem?

In most cases, following a stringent “Inspect before you connect” process every time you work with fiber can minimize contamination and prevent costly repairs.

Evading the “icebergs” in your network

The most critical element to safeguarding quality fiber connections is ensuring a proper end-face condition; essentially, watching for your network’s icebergs before they become a problem. Network uptime and signal performance utterly depend on perfectly aligned and thoroughly clean end faces. When working with fibers only a few microns wide, any contaminant can be catastrophic.

Contaminants exist all around your network, whether it’s dirt, dust or oil. These contaminants interfere with light transmission along your fiber, causing back reflection and insertion loss—all of which means your network isn’t working the way it should. The allowable margin of error is tiny, and proactively inspecting and cleaning end faces, organizations will enjoy reduced downtime, optimized signal performance and minimal network equipment damage.

Here are some of the most common sources of fiber connector contamination:

- Dust Caps – These can still be contaminated from the source of production or mishandling

- Bulkheads – This is where most particles can reside due to not inspecting before connecting

- People – Mishandling fiber is always a factor to keep in mind when servicing your optical network

- Environment –Whether it’s dust during new construction or outside in the weather, contaminants are everywhere

- Test Equipment – Test leads should always be inspected, and if necessary, cleaned prior to testing to prevent cross contamination

Standards are high; tolerances are low

Optical networks have come a long way, and production design techniques have eradicated most of the difficulties in achieving core alignment and physical contact between connectors.

But even with these advancements, the challenge to maintain a pristine end face remains. The VIAVI white paper, “Testing Parallel Optics” describes just how much damage can occur from dirt, as well as detailed instructions for inspection, cleaning, and (re)inspection.

Visual inspection is the only way to know whether an end face is truly clean, but human eyes aren’t reliable enough. The goal is to eliminate any variability in the process, and that’s where standards like the IEC 61300-3-35 come in. This standard sets the inspection requirements for connector quality and in determining replacement or cleaning. A microscope specifically designed for fiber inspection is the only way to determine without a doubt whether connectors are clean before they are mated.

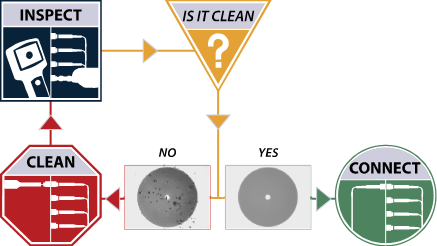

Inspect Before You Connect- a repeatable process for repeatable success

It doesn’t matter whether the connector is brand new out of the box or has been in the field for years. Always—always—inspect before you connect. These preventative measures when installing and maintaining your network will save you both money and time.

- Inspect First – Even if you are dealing with a new connector, inspect it with a tool specifically designed for the purpose. You only want to clean the connector if it’s necessary

- Clean (if necessary) – Make sure to clean both sides of the connection – even if they are difficult to reach. If you find contaminants, use a cleaning tool and solvent with an optical-grade wipe to get the job done. Don’t ever try to save money by reusing wipes. If you do, you’re just creating new problems by being penny wise and pound foolish

- Re-inspect – Once you’ve cleaned each connector, inspect them again with a probe microscope to make sure all contaminants are gone

- Connect – With both sides cleaned, inspected, and then cleaned again if necessary, it’s time to plug in with the assurance that all contaminants are gone

Inspect Before You Connect

Conclusion

Considering the importance of network uptime, equipment reliability and signal transmission speeds, recognizing the importance of clean connectors is a must for optimal performance.

Remember, something as simple as a block of frozen water took down the most modern and supposedly unsinkable Titanic. A speck of dust can do the same to your network, sinking your company’s productivity into an abyss.

For more info on fiber inspection including articles, product info, the IBYC video series and more, visit us at viavisolutions.com/inspect.