Fiber Testing — Get the Right Perspective

When you look at this image, do you see a chalice? Do you see two men in profile? Now that I’ve mentioned both images, can you see both images at once? Fiber testing can be like this trick, you have to be able to see more than what is obviously in front of you. In other words, to ensure that a fiber is operating at peak performance, you need to be able to view its behavior from multiple perspectives.

When you look at this image, do you see a chalice? Do you see two men in profile? Now that I’ve mentioned both images, can you see both images at once? Fiber testing can be like this trick, you have to be able to see more than what is obviously in front of you. In other words, to ensure that a fiber is operating at peak performance, you need to be able to view its behavior from multiple perspectives.

So how can you gain better perspective on the fibers you test?

Well, of course, you can always do nothing (and gain nothing). Some techs practice ‘plug and pray’ and forgo fiber testing, just hoping for the best. However, for me, this simply delays and increases potential future operational costs (OpEx). At some point, a fiber link will not go into service smoothly or a recently activated link will fail. Then you must spend additional time fault-finding or rolling a truck to start troubleshooting—both of which incur additional OpEx costs that could have been avoided with a little testing up front.

The Basics

Network equipment vendors provide specifications at which their optical systems perform correctly. Typically, these specs detail an optical loss budget and optical return loss limit, so simple Insertion Loss (IL) and Optical Return Loss (ORL) tests should meet those basic requirements:

- IL should be below a specified level to maintain good Optical Signal to Noise Ratio (OSNR) for an optical transmission link so network equipment (optical receivers) can receive data in decent shape.

- ORL should test within limits to minimise optical power being reflected back at a laser which could cause data errors or losses and in the longer-term potentially damage the laser.

The IL value is the same in both directions along a fiber link (O-to-E and E-to-O); however, a bi-directional (bi-dir) measurement will give a more accurate result. ORL may be different in each direction, so a bi-dir measurement for ORL should be mandatory.

While IL and ORL tests are crucial, another simple fiber test, OTDR, is often passed over due to cost, time, or presumed complexity concerns. Bi-dir IL and ORL tests are the minimum requirement, but there are problems they can’t detect and faults they can miss. And, of course, if your IL/ORL test fails, what’s the first thing you’ll need to efficiently troubleshoot a fiber link? An OTDR.

Beyond IL and ORL Fiber Testing

What’s beyond IL and ORL tests? All the information about the true total length of a fiber link, the lengths and losses of the various fiber sections, how many splices or connectors there are, and how each impacts the overall link performance. An OTDR characterizes these events by showing how reflective they are (how much light they reflect or backscatter) and what optical losses they add to the link. Too much of either are both reasons an IL or ORL test might fail. OTDR can also find other potential faults like bends—as well as the distance to those faults.

Connecting your OTDR at one end of a fiber link to test is sometimes referred to as uni-directional (uni-dir) OTDR testing and by including uni-dir OTDR testing you pre-empt spending more time, effort, and money later (not to mention avoiding poor customer experiences).

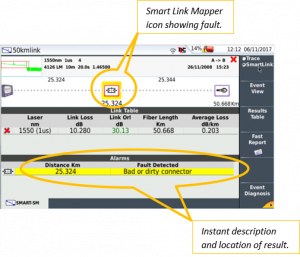

Interpreting these OTDR traces can be a little intimidating so any decent OTDR will automatically convert a trace into something easy to read and identify the various events. VIAVI uses a Smart Link Mapper feature with simple icons as shown below.

So, you’ve done your uni-dir OTDR fiber test and you’re in great shape, right?

Unfortunately, not always.

Bi-Directional OTDR Fiber Testing

A uni-directional OTDR fiber test is not all you need for a comprehensive view. Best practice is to use bi-directional OTDR fiber tests to reveal more detail and correctly diagnose issues (or non-issues), for example:

Hidden events:

Bi-dir OTDR fiber tests can reveal events hidden by OTDR dead zones where events that are close together could be missed and shown as a single event, the reflected (or backscattered) light from the first event means that the light reflected by a nearby event, just after the first, is swamped or missed by the OTDR. Testing from the other end (far end) of the fiber link would reveal that second event so you have a more accurate view of what is in the real/actual fiber link.

Gainers:

The problem of the ‘gainer’ is an event on an OTDR trace with a negative loss. This means it appears to amplify and reduce the loss of the fiber link, which is impossible. This produces a negative connector or splice loss (splice A in the first OTDR trace) and usually a corresponding loss that’s too big (splice B), neither of which would pass scrutiny or be signed off as ‘ok’. This is typically due to mismatched fibers in a link where the launch and receive fibers do not match the fiber under test. It could also be due to differences in fibers that have been spliced together to make a link, maybe as part of a repair.

The problem of the ‘gainer’ is an event on an OTDR trace with a negative loss. This means it appears to amplify and reduce the loss of the fiber link, which is impossible. This produces a negative connector or splice loss (splice A in the first OTDR trace) and usually a corresponding loss that’s too big (splice B), neither of which would pass scrutiny or be signed off as ‘ok’. This is typically due to mismatched fibers in a link where the launch and receive fibers do not match the fiber under test. It could also be due to differences in fibers that have been spliced together to make a link, maybe as part of a repair.

Differences between manufacturers or even manufacturing batches can lead to variances in the backscatter coefficient of a fiber and when spliced to another fiber results in a ‘gainer’. Bi-dir OTDR testing allows you to average out these manufacturing/ backscattering/ measurement differences to give true event loss, helping you diagnose whether a splice, connector or section of fiber really is a problem and needs to be replaced, potentially saving you time and money or stopping you from abandoning a good fiber link.

Once the losses for the splice events are matched and averaged you get the true or actual loss and as you see, it’s not an optical gain but it’s also not an excessive loss that requires remedial work. Actual loss is less than 0.1dB which it considered to be the loss limit for a good fusion splice.

Of course, for any tech or contractor, the time it takes to perform bi-dir testing may be a concern. It potentially means more time on site and more report generation, leading to fewer jobs completed per day. But it’s equally important to think about what you will save in terms of the future:

- Pre-empt poor customers experiences due to missed fiber faults

- Minimise physical returns to the site for troubleshooting

- Avoid throwing out perfectly good fibers

- Bolster your reputation for “getting it right the first time”

The price you pay for poor testing is about more than just money (although, if you’re a contractor the financial price you pay for a site revisit will likely be from your own pocket). Your reputation is only as good as your last job. Doing your work following best practices is an opportunity to impress and the bi-dir OTDR test shows you are thorough, taking the job seriously, and thinking about your customer’s business too. Ultimately, the fact that you conduct comprehensive, proactive tests is a way to differentiate yourself from your competition.

No one wants to have to return to a site to do fix something that should have worked already (the embarrassment! the shame!). So, do it right the first time—do the OTDR testing.

For more on tips and best practices for fiber testing, read the other posts in this series: