Why Do Subsea Cable Cuttings Happen, and How Can We Reduce the Impact?

Last weekend, an undersea cable in the Red Sea was cut, disrupting internet access in the Middle East and Asia. It wasn’t until three days after the cutting that it was reported that it was likely the result of commercial shipping.

This isn’t the first instance. Four Red Sea cables were cut last February by the anchor of the sinking MV Rubymar. The internet monitoring organization NetBlocks said the outage has resulted in degraded connectivity, including in countries as far away as India and Pakistan.

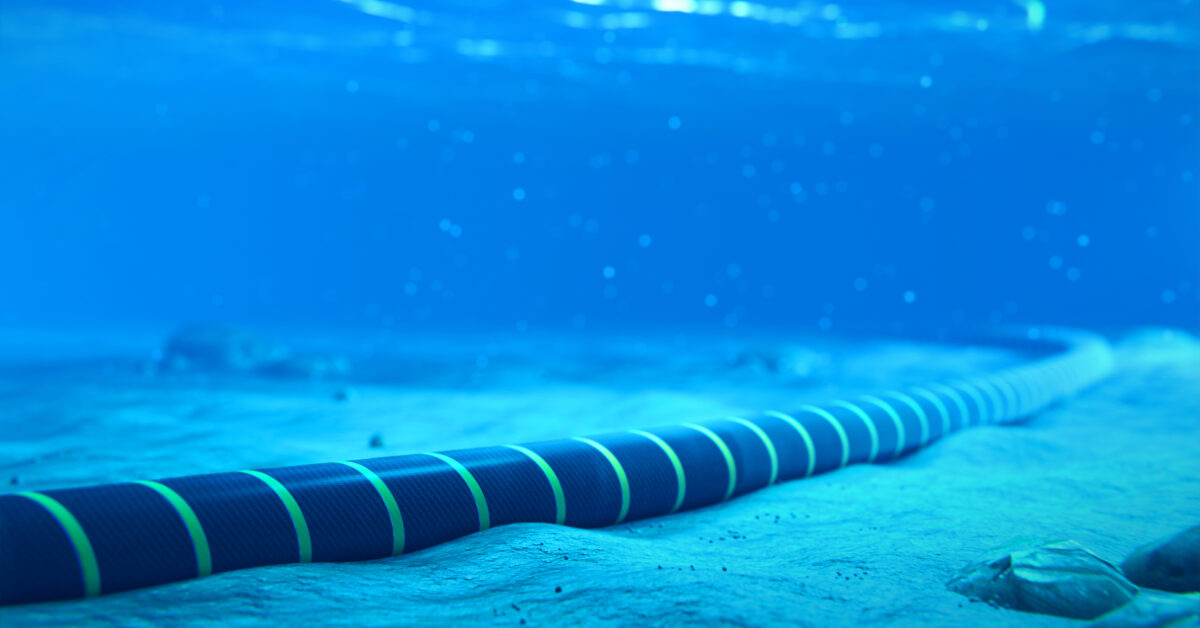

With large cable deployments worldwide, the need for permanent surveillance is becoming more critical. In addition to data cables, power cables from off-shore windfarms, as well as oil and gas pipelines also form part of the critical power located undersea that is prone to both attack, accidental damage, and natural degradation.

According to the International Cable Protection Committee, there are approximately 1.7 million kilometers of undersea cable, and these cables undergo 150 to 200 incidents each year. In this blog, we’re going to take a look at what physical protection techniques exist for protecting such critical infrastructure, how the effects of these incidents can be minimized, and how to better attribute the cause of damage.

Physical Protection

Subsea cables can span oceans, with Meta reportedly planning a 25,000-mile around-the-world-cable. This makes them incredibly hard to protect, with armor and burying being the main techniques.

However, these are not always possible. Burying cables deeply enough to protect from anchors is costly. Even then, the cables are still prone to earthquakes and similar seismic events. Increasing the cable’s armor is also costly, and not just in terms of the cable itself but its deployment too.

The final option that exists is active patrolling on the surface above the cables. This is feasible for relatively small cables, such as in Finland’s stretch of the Baltic Sea, but it would be prohibitively expensive to do this at scale.

If we can’t cost-effectively protect against the cut, can we reduce the damage it causes?

Minimizing the effects of a cut

Cable cutting is both common and costly, with approximately three fourths of insurance claims related to offshore assets being a result of a cable cut. The average downtime is 62 days and the average repair costs £12.5m. And that’s before the cost of the downtime on the operator and all those relying on it.

Repairs are often made harder by the difficulty to pinpoint the exact location. For example when a cable running along the West African coastline was damaged, the accuracy that the Nigerian Communications Commission spokesperson was able to pinpoint it to was “somewhere in Cote d’Ivoire and Senegal.”

There are, however, techniques that can better locate the damage, and give early warnings. Notably, distributed fiber optic sensing (DFOS) technologies are already being used to protect pipelines and other critical infrastructure around the world.

Three techniques (Raman, Brillouin, and Coherent Rayleigh) measure the way light travels along a cable to quantify changes in strain, temperature and any vibrations that the cable is being subjected to (see here for more detailed information). Implementing these enables the fiber itself to be used as the sensor, with sensing points being continuous along its length.

Using a monitoring system to undertake Coherent Rayleigh backscattering analysis, for example, enables distributed acoustic sensing (DAS) and with it the identification and classification of a range of vibration-based factors, including seismic events and the cable being dragged by an anchor.

And while this approach may not be able to prevent an act of sabotage, DFOS techniques do allow the location of a cut to be precisely identified to speed repairs. And they allow the cable’s operator to understand what led to the cut. Furthermore, because an anchor dragging along the seabed (or trawling/digging) has an identifiable audio/vibration pattern, it can also give the operator an early warning. Because all boats are (in theory) required to operate a location-transmission beacon, the operator can then identify the boat about to cause damage and warn them before the cable is cut.

Preventing failure

With these cables being critical to a country’s operations, the need to identify cause is essential.

Cuts/failures don’t only come from sudden events. The nature of their environment means cable failures can routinely happen from natural causes over long periods of time too.

To detect this, a second DFOS technique called distributed temperature and strain sensing (DTSS) can be used to detect both manufacturing defects and deterioration/ fatigue from continually being dragged over the sea floor by currents and snagged by rocks.

Implementing this enables work to be scheduled more cost effectively and with the minimum of disruption before an outage occurs.

For power cables coming from offshore windfarms, there is an additional risk of failure from thermal damage from excess power transmission reducing the cable’s lifespan. Here, the Raman DFOS technique scattering for distributed temperature sensing (DTS) can be used to continually monitor and identify when transmission needs to be reduced.

When will such technologies be in operation?

DFOS systems, such as VIAVI’s NITRO Fiber Sensing, are already in use to protect a range of critical infrastructure, from pipelines to military facilities, but it’s far less common in undersea cables.

And while the need for permanent surveillance is becoming more critical, it will happen as new cables are rolled out.

However, the number of new subsea cables for telecom and utilities is rising quickly, to meet the needs of data center interconnectivity (DCI) as well as for communication networks and power transmission. While there is no legal mandate that sensing capabilities be implemented, cable owners and infrastructure operators are increasingly looking to integrate the technology. The pressure to do so is increased by these cables starting to be listed as national critical infrastructure, especially when rolled out via government-backed initiatives.

Adding to this, many existing cables are reaching the end of their operational life and will need replacing or upgrading.

So while the technology currently rarely used for subsea cables, its benefit/cost means this will change quickly and hopefully the next major outage, along with its cause, will be pinpointed more quickly and accurately.