The Role of AI in Fiber Optic Connector Inspection and Analysis

Later this month, the VIAVI team will head to Washington, DC and Copenhagen for SCTE TechExpo and ECOC (European Conference on Optical Communication). In this blog, we will examine the increasing need for and the role of AI in fiber optic connector inspection, as well as highlight one of the key innovations on display at these shows: the INX™ 760 probe microscope.

This device was launched in March 2024 for automated inspection and analysis of simplex and multifiber connectors and is the industry’s first such device to implement AI-driven image analysis.

Automated Connector End Face Analysis

It’s important to note that AI is likely not needed for all types of automated fiber optic connector end face analysis. AI should be used to complement classical algorithm-based techniques rather than as a standalone tool. In many situations, AI is like using a hammer to crack a nut… and a computational resource heavy hammer at that.

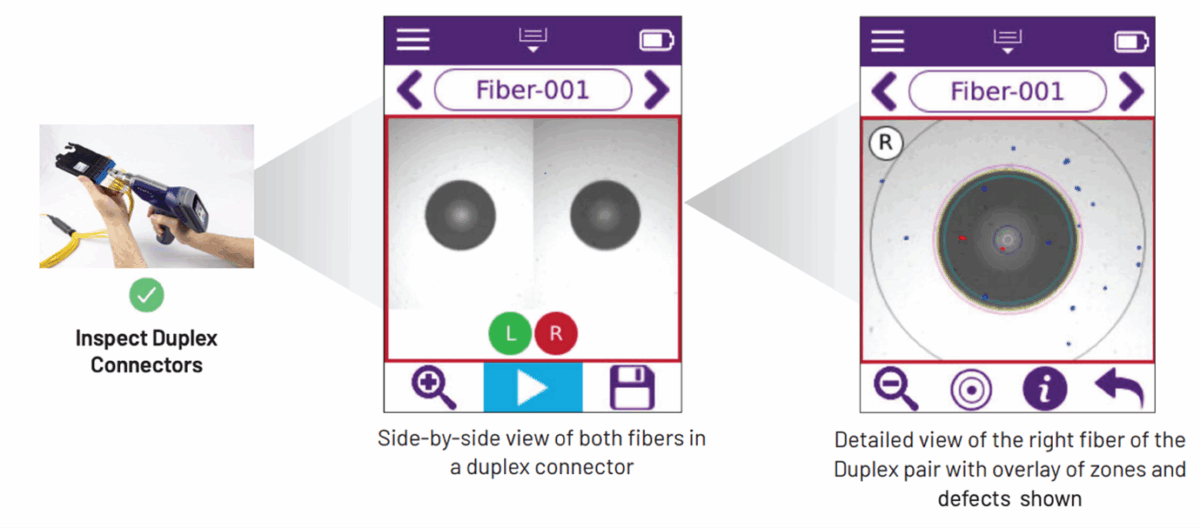

Indeed, when undertaking automated analysis of uniform-looking ceramic ferrule connector end faces, classical analysis remains the most efficient tool for evaluating images and detecting defects. This classical analysis can be seen in Figure 1, where a probe microscope is being used to inspect the end faces of a duplex connector, with each side of the connector consisting of an optical fiber surrounded by a ceramic ferrule. In this, the fiber appears dark against the bright ferrule and the microscope can automatically detect defects and highlight these for easy assessment of end face acceptability.

Classical image analysis relies on deterministic, rule-based algorithms to detect defects such as scratches, pits, and contamination. This technique is fast and efficient, making it the best option for inspection of connectors with ceramic ferrules. And using classical analysis, an INX 760 microscope with the appropriate tip can automatically inspect a duplex fiber optic connector in a single test in less than five seconds.

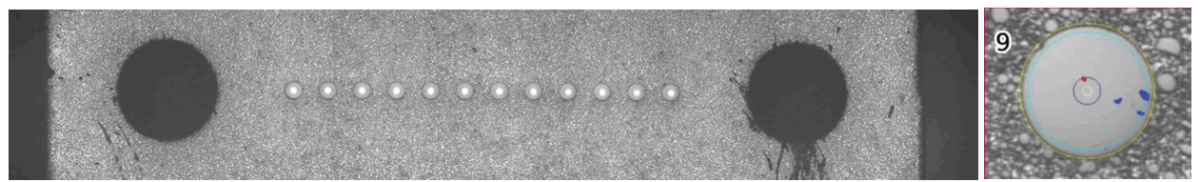

However, as data throughput increases, so too does fiber density. For example, the data center industry is in the process of switching to denser multifiber connectors such as MPO, MMC and SN-MT. These connectors use rectangular MT ferrules with multiple fibers organized in one or more rows (see Figure 2).

Figure 2: the 12 fibers in a rectangular high-density MT-ferrule connector (left) and zooming in on a single fiber (right)

In this image, 12 fibers are aligned in a single row within the MT ferrule. In contrast to a traditional ceramic ferrule, the ferrule material no longer presents as a uniform white background. Instead, it is a glass-filled polymer where some of the embedded glass fibers can resemble optical fibers or defects laying on top of the ferrule. As a result, automated inspection of multifiber connectors with MT ferrules is more challenging.

Enter AI.

The Tradeoffs of AI

AI-driven image analysis uses machine learning models trained on large datasets. This approach is more robust in handling complex or noisy images like those presented by MT ferrules.

AI requires more computational resources, specifically more powerful processors and greater memory capacity. The INX 760 microscope features 2.4X the processing power of the nearest competing probe microscope and 2X the memory to enable real-time, on-device AI inference without reliance on cloud connectivity, ensuring fast and secure analysis in field inspection applications.

The INX 760 microscope delivers the best of both. Its classical algorithm techniques provide rapid, energy-efficient analysis and these are augmented by its AI-driven image analysis for more complex analysis scenarios, such as those involving MT ferrules.

See the INX 760 Microscope in Action

VIAVI will be demonstrating a wide range of technologies for fiber inspection at two upcoming shows. Visit us at booth J1285 (SCTE TechExpo) and stand C3113 (ECOC).

We look forward to seeing you there!